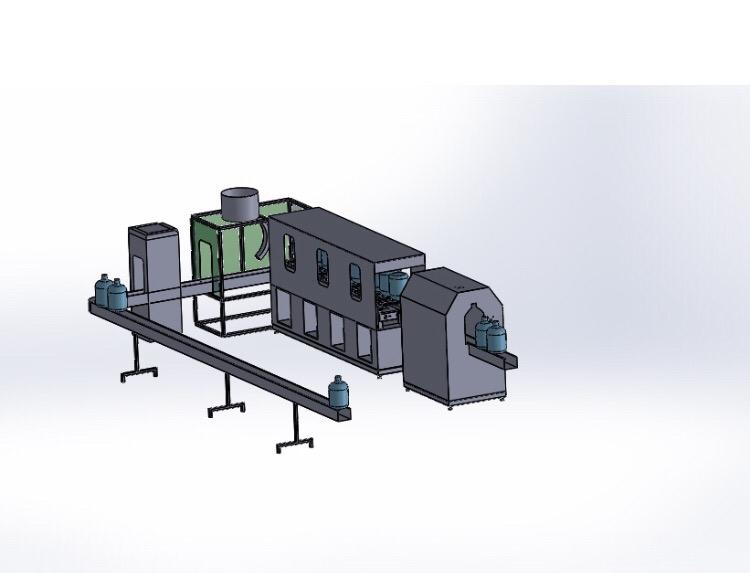

BOTTLE WASHING AND FILLING SYSTEM AND TECHNICAL SPECIFICATIONS

General Specifications

Washing Cycle

Bottle Emptying Section

Carboy Filling System Advantage of this system

Automatic Capping System

Cap Sterilization

- Completely AISI 304 Stainless Steel Construction

- Filling valves are AISI 316 Stainless Steel

- Cabins in the Bottle Loading and Discharge areas are made of Plexiglass material

- There is an Internal Lighting System at all stages in order to control the washing stations

- Large side windows for easy viewing of Wash Stations

- Stainless Steel Water Circulation System

- Stainless Steel Water Circulation Pumps

- Modular Construction

- Stainless Steel Conveyor Chains

- The electrical installation has been designed in accordance with the CE Regulations.Electrical control panels and buttons are insulated

- SIEMENS or DELTA PLC with touch screen operator panel

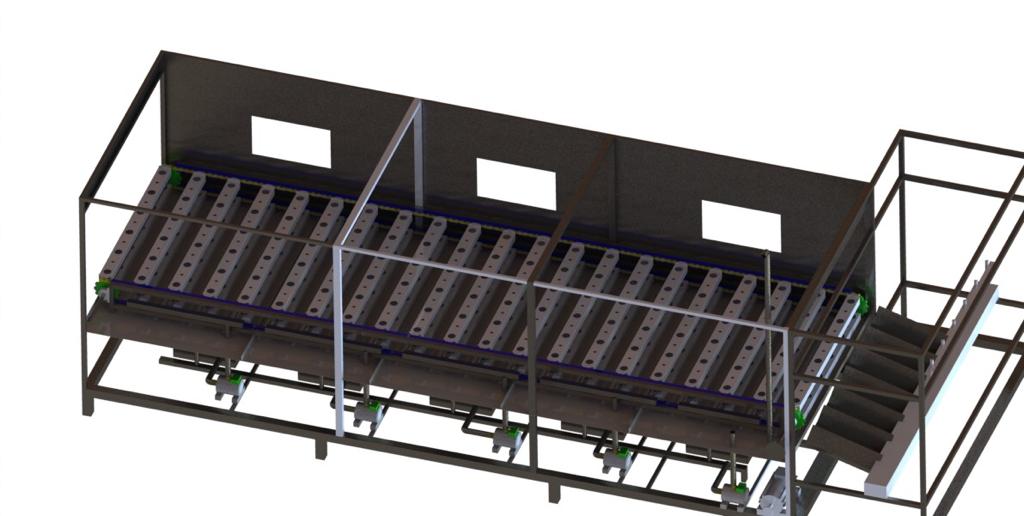

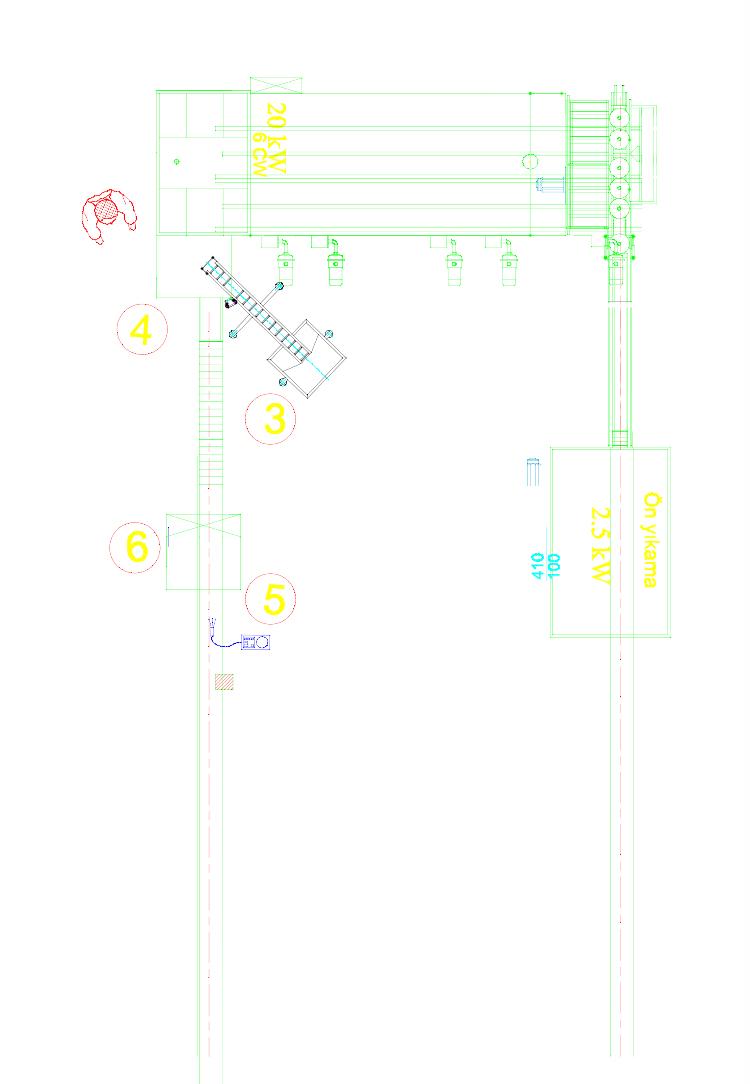

- There are 5 Different Stainless Water Tanks in the Washing Section

- Stainless Steel Pre - Washing Water Conversion Tank(Number 1 in Layout drawing)

- Stainless Steel Electric heater 2 Tank(Number 2 in Layout drawing)

- Stainless Steel Water Conversion Tank(Number 3 in Layout drawing)

- Stainless Steel Water Circulation Tank(Number 4 in Layout drawing).In the final rinse system, the entire bottle is filled with ozonated water.In this way, it rinses after sterilizing and delivers the water to the lower tanks

- Final rinse system with water in a stainless steel tank(5)

Washing Cycle

- Internal and external pre - washing process is performed on the carboy with the water coming from the Water Cycle.Tanks made of Stainless Steel

- The inner and outer washing of the bottle is done with the water coming from the detergent +water mixture tank.Water temperature is regulated by water temperature sensors and thermostat system(around 70(C)).The water level is adjusted automatically

- There is a nozzle system that prevents residual washing water and detergent at the bottom of the bottle, and works with compressed air passed through micro filters. (Compressed air will be supplied from an air compressor)

- The inside of the bottle is washed in 2 stages with Ozonated Water or Natural Spring Water to make sure that the bottle is completely washed and rinsed

- High - pressure washing effect(4 bar)

Bottle Emptying Section

At the end of the wash cycle, the bottles are automatically loaded onto the exit conveyor.

Carboy Filling System

- Pressurized water filling system that prevents the filling water from overflowing,

- System does not fill if there is no bottle,

- A mechanical system centers the containers under the filling valves,

- System does not require maintenance and works with 99 % filling accuracy.

- Works with high filling sensitivity(no overflow)

- Maintenance Free Working Feature

- Precise Water Level Control

- Mechanical system that brings the bottles right under the Filling Valves

- Works on the principle of no bottle no filling

Automatic Capping System

- Automatic Cover Feeding System and Cover Sorting System

- It works with the principle of “no bottle no capping”

- Automatic Linear Capping System with stainless steel pallet(Caterpillar Type)

- The capping system is working by press on cap

- The bottle is stopped under the closing head to ensure the perfect centering of the cap on the bottle

Cap Sterilization

- In - cap spray disinfection system with Ozonated Water

- UV Cover Disinfection System