Syrup Room & Mixer Unit

Wearepleasedtomake an offerourcustomers SUPERMIX. SUPERMIX 10.000 Unit Type for the production of soft drinks with hand with out CO2, from the components water and syrup. Technical features of SUPERMIX syrup & mixing unit are as follows:

General Specifications

- Capacity :max. 10.000 l/h beverage

- Syrup & Mixer Unit for the production of soft drinks with and without CO2, from the components water and syrup. The syrup & mixer unit consists of AISI 316L quality stainless materials, all sealing parts are suitable for food production.

- The main chassis of machine will be 80x80x3 mm AISI 304L stainless profile.

- AISI 316L

- Two proportional valves are used to keep the CO2 values in the machine under control: First proportional valve that can automatically adjust the amount of syrup required for mixing is used in the syrup mixer unit.The other proportional valve is used to adjust the machine capacity.

- A CO2 flow meter that can adjust the desired gr / lt for the final product is used in the unit.

- Syrup flowmeter, which can measure the solidity (brix) level of syrup, is used.

- The final product flowmeter is used to control the WATER + SYRUP transition in the final product tank.

- The plant is delivered readily installed and works fully automatically.

- Alarm probes will stop the plant when one of the ingredients is missing. All alarms are shown visually.

- Its include chiller unit

Structure and Working System of the Machine

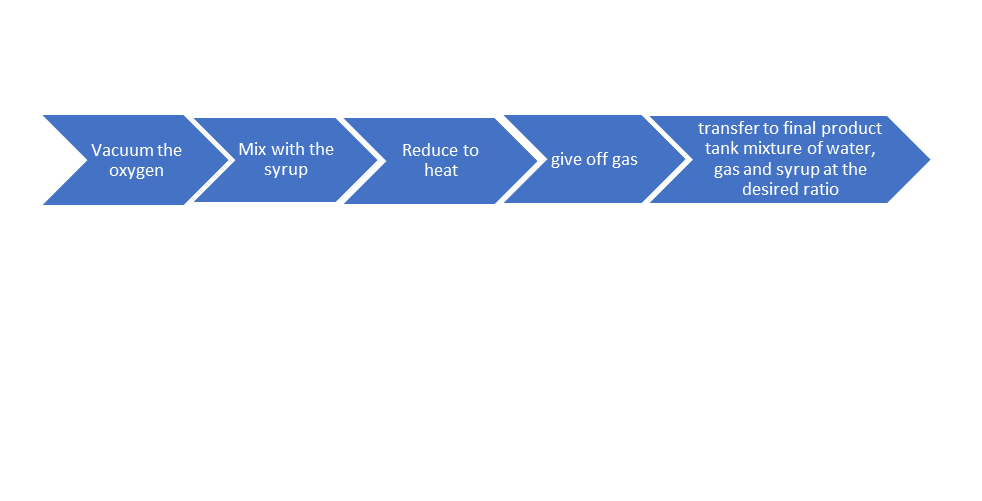

Vacuum Section:

The oxygen in the spinning water, which is 20-25 ° C, is thrown into the atmosphere with the help of pulverizer.

Syrup Unit:

The tank in which the high brix value syrup is kept ready for use.

Mixing Section:

Section where deoxygenated water is mixed with high brix-valued syrup at the desired rate. In the vacuum tank, the sputtering water is sucked with the help of a pump and the syrup with high brix is sucked from the syrup container and sent into a single mixing pipe.

Heat Exchanger Section:

It is used to reduce the temperature of the mixed product to 7-8 ° C in order to gasify it.

Gasification Unit:

The finished product is sucked by the mixing pump and passed through the plate heat exchanger. After the temperature is reduced to 7-8 ° C, the gasification process is opened by opening the gasification valve.

Final Product Section:

It is the tank where the mixture of water, gas and syrup at the desired ratio is kept for filling.

ELECTRIC AND ELECTRONIC MATERIALS USED IN THE MACHINE

Problems that may occur in syrup & mixer machines are generally related to electronic and electrical parts, not mechanical. The strength of the electronic and electrical system depends on the quality of the electronic and electrical materials to be used in the machine.For this reason, it may be necessary to pay attention to where the machine is produced, as well as from which brand of component it is manufactured. Attention should be paid to where the machine parts are produced rather than where the machine was produced.

- Endres + hauser brand flowmeters 3 pieces

- Vacuum pump brand is Gücüm

- The brand of water, syrup, carbonized, circulation pumps is sesinoks

- Exchanger brand Inokstek or Gea

- Brand of actuator valves is Gea or Guth

- Brand of pressure and vacuum sensors Sick

- Brand of level control and water safety sensors IFM

- The brand of materials used in electricity is Telemecanique

- PLC's brand Omron

- Festo brand of air conditioners

- The magnetic level float brand is Balluff

How system works?: Summary of Process Scheme